Regardless of the industry you work in, safe and correct manufacturing should always remain your top priority. As the market has become more competitive as a result of the increased prices of materials or the fluctuating economy, businesses have found it extremely challenging to make profits.

If you’re experiencing a significant manufacturing challenge, you should consider developing a relationship with a precision machine shop to produce high-quality manufacturing parts that your customers can rely on in such turbulent times.

If you’re still thinking about whether to partner with a machine shop for your precision machining needs, below we present several ways how such a trusted shop can add massive value to your business.

Manufacture Accurate Parts

Unlike other manufacturing methods, precision machining uses high-speed lathes that give your parts consistent accuracy. Precision machine shops are known to utilize equipment that intakes CAD-based blueprints to interpret design instructions and then carry out the operation. This allows them to perform machining tasks with incredible accuracy and with varied multi-axis positioning.

What is even more important to highlight is that CNC machines allow users to repeat the same operation for higher accuracy of their part in a consistent and timely manner. These machines are specially designed, and for this reason, they outperform any human or machine when it comes to accuracy, speed, and reliability. As a result, precision CNC machining shops can provide you with error-free machined parts in less time but with the same quality.

Prevent Scrap Wastage

More often than not, manual processing leads to excessive scrap wastage. Since materials are costly, this impacts profitability. When you add the labor costs for inspection and sorting, be ready for your expenses to double. Precision machine shops can greatly benefit your business as they use CNC technology to make parts better and get little-to-no wastage.

The robust functions of CAD and CAM software allow the CNC machine shop to flawlessly visualize the design and identify the optimum process before turning or drilling the materials. This allows businesses to reduce internal scrap wastage to great extent, which will also save you money.

Help Your Business Save Money

One of the leading benefits of working with a precision machine shop is that it helps you save money. Because of the comprehensive nature of precision machining, the parts you need can be produced with minimal waste and labor, and very low chances of error. On top of that, most precision machine shops can help you save money on raw materials and supply chain management as they have their inventory of materials.

Compared to doing it in-house, CNC machine shops can save a lot of cost in terms of materials and employee salaries, while providing a better ROI in the long run.

Provide Professional Expertise

Another valuable benefit of precision machine shops is that they have a team of professionals who are adequately trained in the craft of machining. Their technical experience helps them understand your business's specific needs and requirements and manufacture parts quickly and professionally.

They’re also adequately trained to work with specialized machines that cannot be easily operated by a novice. These professionals can also help you during each phase of your manufacturing journey so you can obtain a better understanding of the overall process

Machine a Wide Range of Materials

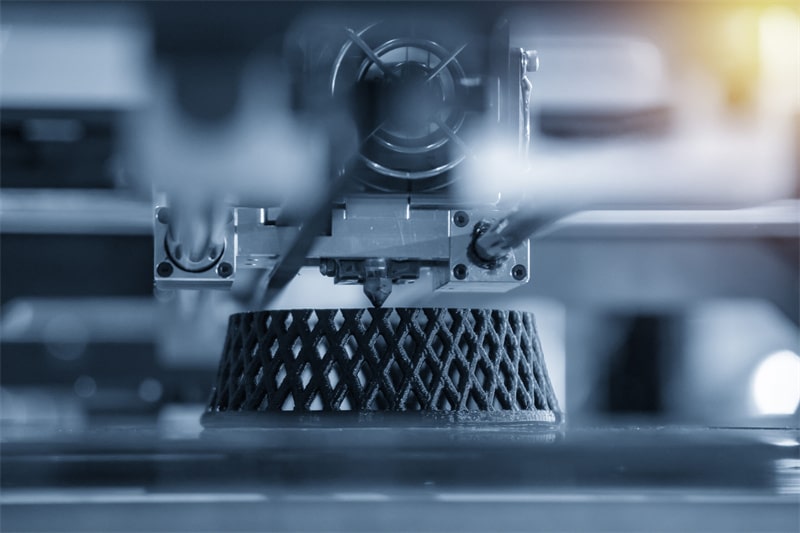

Even though a majority of businesses use 3D printing and other manufacturing techniques, they offer rather limited options concerning materials. Although they provide various material filaments, 3D printers still need to catch up when it comes to a particular set of metals used in specialized industries.

High-precision machines can work with all types of materials, including metals such as alloy, titanium, aluminum, plastic, foam, wood, and so on, to create accurate parts. This gives you an advantage when manufacturing your parts. The great thing about outsourcing your needs to a precision machine shop is that you can machine almost any material to a specific shape and in the right quantity.

Get Access to Emergency Machining Services

Businesses can be faced with emergency situations in which manufacturing demands have to be met in a short time. For such scenarios, precision machine shops can offer dedicated emergency machining services.

By having the opportunity to get the expertise of trusted machine shops at any given time, you can save your business from having to deal with stressful emergency manufacturing situations.

In Closing

As you may already know, there are many ways precision machine shops can assist you in manufacturing your parts. By teaming up with a precision machine shop, you can accurately manufacture any part and save yourself from unnecessary costs and headaches.

A trusted precision machine shop will use its resources and have a team ready to help you overcome any manufacturing challenge.