Six Sigma has created a niche for itself among the topmost methodologies developed for managing business processes effectively and efficiently.

Along with establishing a culture based on continuous improvement, Six Sigma is a set of tools and techniques that help in reducing variance, removing defects and finding out the primary reasons behind errors, enabling organizations to develop better products and services for their customers.

Although a majority of the population associates Six Sigma with manufacturing, it is applicable to all the types of processes in any industry. Professionals gain expertise in Six Sigma by attaining level-wise belts which include white, yellow, green, black and master black belts.

This article will make you understand what is Six Sigma, what are its business values, the methodologies and tools used in Six Sigma and applications of Six Sigma. So let’s get started and know what Six Sigma is all about.

Six Sigma Methodologies

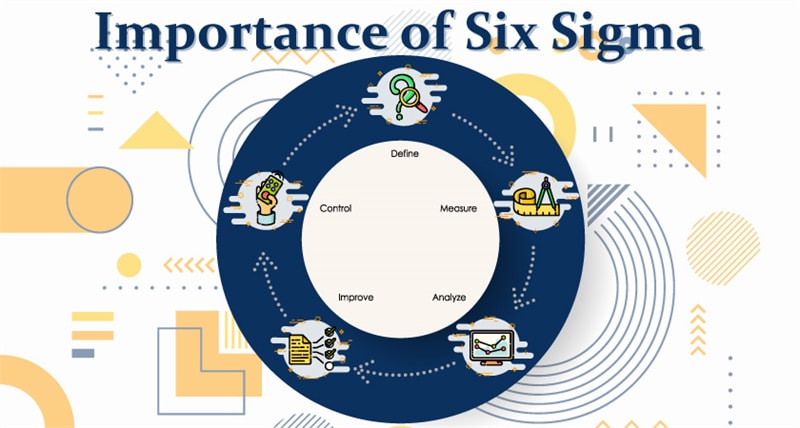

Primarily, Six Sigma comprises two methodologies namely, DMAIC and DMADV. In this section, we will be gaining a basic understanding of these two methodologies.

DMAIC: This method is mainly used for enhancing the prevailing business processes. The letters in the word ‘DMAIC’ stand for:

- D: Define the problem as well as the project goals

- M: Measuring different aspects of the present process in detail

- A: Analyzing data and finding out the root causes behind the defects in a process.

- I: Improving the overall process

- C: Controlling the way the process will be executed in future

DMADV: This method is specifically used for creating new processes along with new products and services. The letters in the word stand for:

- D: Define the project objectives clearly

- M: Measure the important components involved in the process and the product capabilities.

- A: Analyze the given set of data and build different designs for the process, eventually choosing the design that best suits the project.

- D: Design as well as test the details related to the process.

- V: Verify the designs with the help of simulations and pilot program followed by handing over of the process to the client.

Tools Used in Six Sigma

Important tools used in Six Sigma include:

- SIPOC: It is the abbreviated form of Suppliers, Inputs, Process, Output, and Customers. Primarily, SIPOC is a diagram that offers visual answers to questions required for understanding the process. The final diagram is equally important as the steps used to create it and the involvement of team members in generating ideas and brainstorming sessions.

- Stakeholder Analysis: This helps in listing of different stakeholders and assesses the impact of improvement on each one of the stakeholders.

- Voice of the customer or VOC: Different VOC tools like focus groups, interviews, suggestion boxes help in providing data related to the customer requirements and viewpoints.

- The Cause-Effect Matrix: The tool is used for tabulating against effects and helps in calculating the scores which are later on used to rank the causes. This tool helps in measuring the matrix used for selecting inputs one needs to focus upon.

- Data Collection Plan: This tool involves all decisions related to the type of data that needs to be collected, the appropriate sample size, identification of data sources along with the development of data collection sheets and allocation of data collection responsibilities among team members.

- Fishbone Diagram: It is a tool using which a large arrow is drawn and the effects whose causes are assessed are placed in the right side of this large arrow. Once the information on the probable causes is available, brainstorming takes place about the detailed causes and indicated against the corresponding branch.

- Mistake Proofing: When appropriate designs of equipment and processes are used, the possibility of errors get completely eliminated. One of the most popular examples of mistake proofing is designing online forms which can’t be submitted if the given data is incomplete or incorrect.

- Project Management: When a team agrees upon a solution, they implement it in the form of a project. The solution then will be requiring the use of project management tools like planning, communication, monitoring and risk management.

Importance of Six Sigma

Six Sigma has gained a lot of attention since its implementation in the form of a business strategy by Jack Welch at General Electric in the year 1995. Since then it has become an essential part of a broad number of industrial sectors. Implementation of Six Sigma is important as it helps organizations in the following ways:

- Process mapping: Mapping of processes is used by Six Sigma which primarily involves developing flowchart that documents the specific business processes. Documentation involves different aspects of business processes such as employee roles along with decision points involved in overall work performance needed to meet specific client requirements. These flowcharts are further used for making improvement suggestions.

- Removal of variation and waste: Upon identifying the improvement ideas, Six Sigma techniques can be used for removal of waste and variation in business processes. Waste majorly refers to anything that is not contributing anything towards producing a product or service that needs to be delivered to the customer.

- Minimized defects: Implementation of Six Sigma is highly essential for minimizing defects. With the help of Six Sigma techniques, employees can easily identify defects as well as repeated issues that can impact the overall quality of products or services offered.

- Allows Continuous Improvement: Employees with profound training and knowledge in Six Sigma hold the necessary skills of identifying problems or the bottleneck areas that can potentially affect the overall production or performance. In the long run, this process helps in developing high-quality products and services through continuous improvement.

This was all about Six Sigma. We hope this article will prove to be instrumental in imparting a basic understanding of Six Sigma.